Senior capstone Project

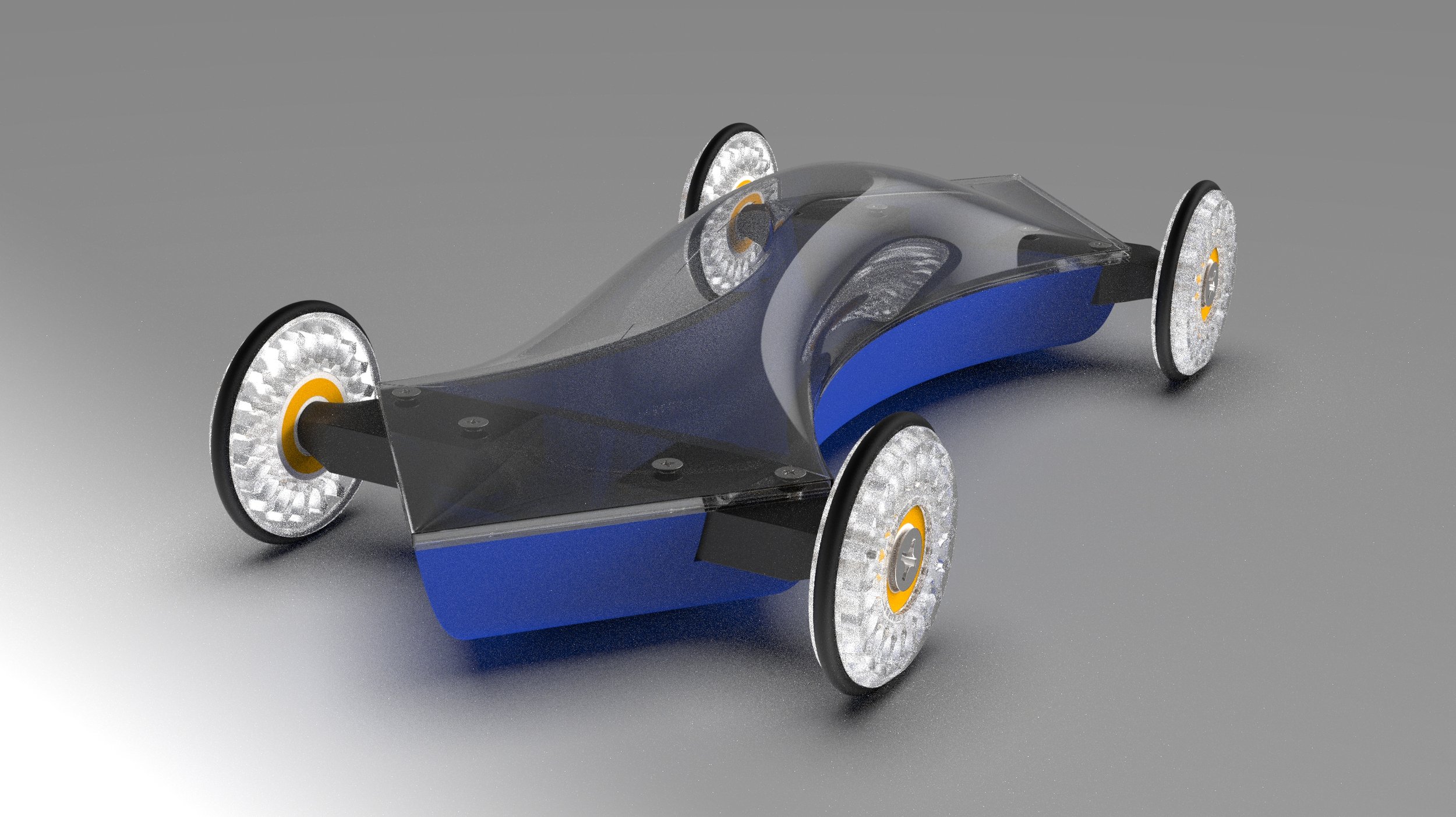

The yearly SUIID Ramp Race asks juniors to use CAD modeling and fabrication skills to produce a race car that will compete in the events of: Vertical Jump Height (how high the car reaches when flying off the ramp), Accuracy (ability of the car to stop exactly on the target), Construction, and Style.

The car is required to contain at least one component that is vacuum-formed from a CNC-fabricated model, one laser-cut component, and also be less than ____ pounds and within the dimensions of _______.

This is a shortened version of the capstone book that fully covers the design process of this project, which can be viewed here

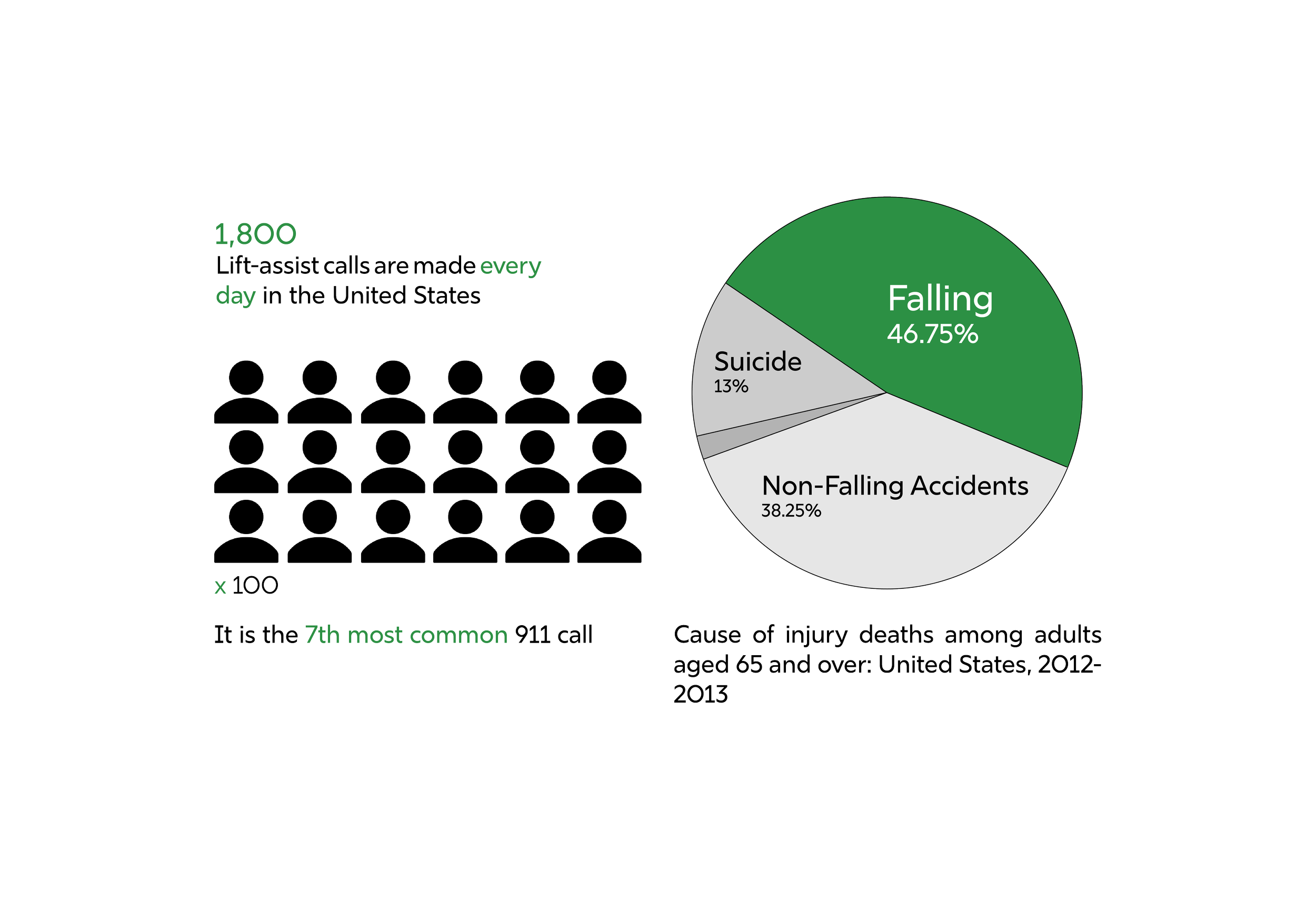

Falling is a major issue

The yearly SUIID Ramp Race asks juniors to use CAD modeling and fabrication skills to produce a race car that will compete in the events of: Vertical Jump Height (how high the car reaches when flying off the ramp), Accuracy (ability of the car to stop exactly on the target), Construction, and Style.

The car is required to contain at least one component that is vacuum-formed from a CNC-fabricated model, one laser-cut component, and also be less than ____ pounds and within the dimensions of _______.

Who am I designing for

Although an assistive device like this could be used by anyone who is at risk of falling, because of the many conditions that can lead to imbalance or slowed reflexes in the elderly as well as the more drastic consequences that result from impact of a fall on an aging body, the elderly became my target audience for this project.

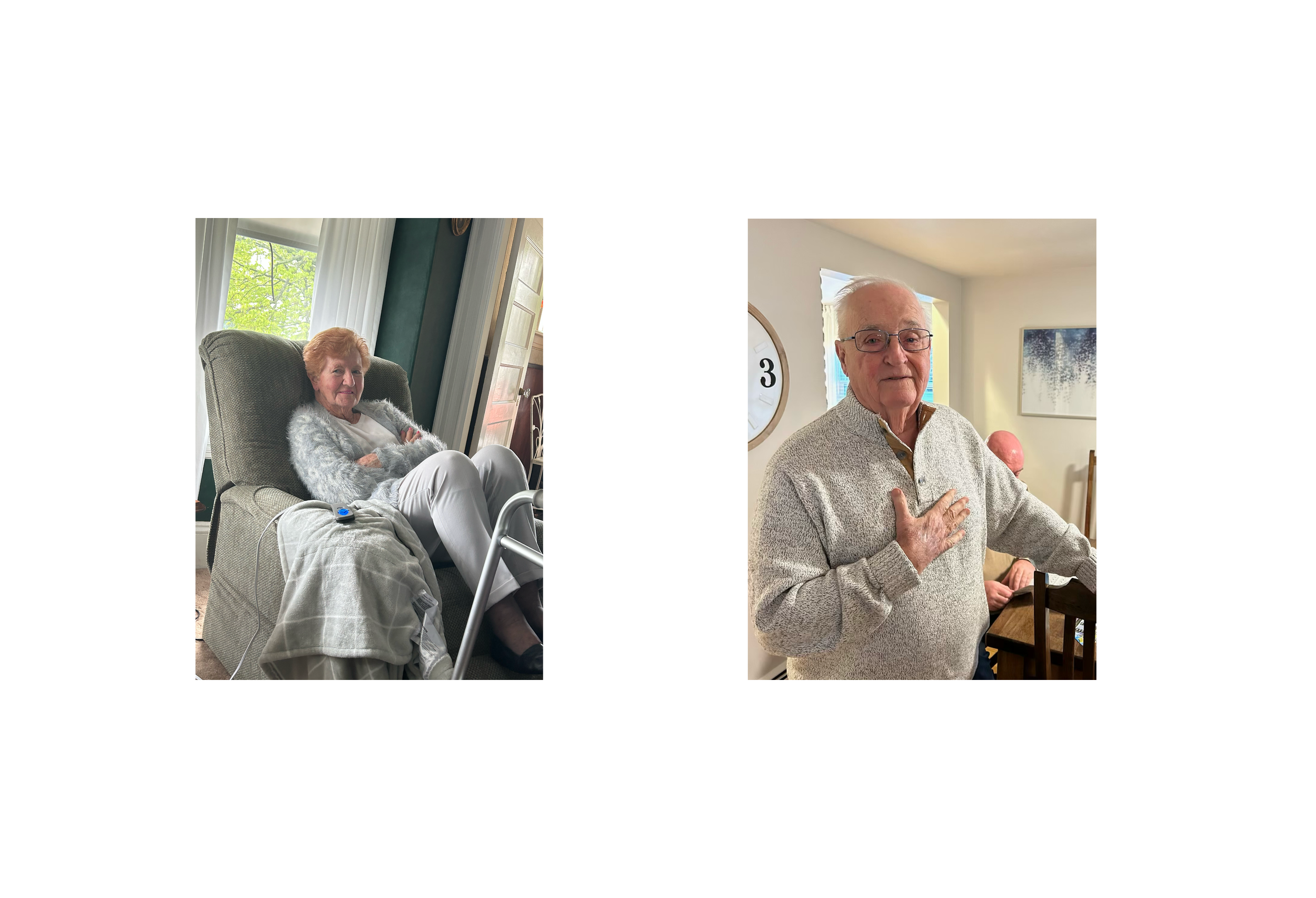

In shaping a user persona, I consulted with my own grandparents to evaluate how they live with falling.

My grandmother Is 91 years old and has Parkinson’s Disease. She falls frequently and sustains major injuries each time, having broken her neck, back, ribs, and wrist since receiving her Parkinson’s diagnosis two years ago. Notably, she receives black eyes from falling as well, resulting from Parkinson’s Disease interfering with her ability to reflexively cover her face or adjust herself while falling.

My grandfather is 90 years old and has become the primary caretaker for my grandmother. He is able-bodied aside from use of a cane, and he lives with my grandmother, alone in the house that she grew up in. His time is devoted to assisting my grandmother, but because of his age he is unable to pick her up from the ground after a fall. Each fall means a lift-assistance call to the fire department.

Considerations for the user

The design that comes out of this process, no matter how functionally sound, needs to account for the user’s needs and preferences to become a product that the target audience will actually use.

To guide the design process I established three core principles:

The design solution has to respect the lifestyle and ideals of the user

The user should be able to continue doing the things that bring them joy, with the design solution not impeding on their ability to wear the same clothes, sit in their favorite chair, etc. In the case of my grandmother, she is a very stylish woman and simply would not use a product that she found ugly or limited her ability to style herself.

For this reason, a body-covering design, like a large vest, is out of the conversation.

The design solution needs to allow the user to retain autonomy

The user should continue to have a feeling of control and independence when using the design solution, rather than feel like the design solution is taking away from their humanity.

For this reason, a large-scale design, such as a tether from the user to the ceiling, is out of the conversation.

The design solution needs to be easy to equip

It is a common issue for elderly people that they wake up in the middle of the night with an urgent need to go to the bathroom. At this time, they are sleepy, in a rush, and in a poorly lit environment. To deal with scenarios like these, the design solution should either be easy to put on quickly or so nonintrusive that it never needs to be taken off.

Designing for prevention

Looking at the problems that the user faces, the solution that addresses the user entirely is a solution that designs for prevention of falls.

The primary function that the design needs to execute is preventing injury caused by falling. With the exception of mobility devices like walkers, every product on the market designed for falling is a protective device. These devices attempt to cushion the user and mitigate the impact of their fall to reduce injury.

The problem with designing only around injuries is that it still leaves the user with the problem of getting up after falling. The aforementioned market solutions accept falling as an inevitability, and attempt only to mitigate the consequences of falling. These devices are a visual reminder of unsolved vulnerability, and this connotation leads people in need to push back against using these devices.

A device that prevents falling enables not only the safety of the user, but frees up the lives of those around the user. Loved ones no longer need to worry about the user as they are self-sufficient and won't need to be picked up or driven to the hospital at a moment's notice. Emergency services will have their lines freed up and be able to help more people.

Designing for prevention means empowering the user by solving the issue of falling entirely. The end product should make the user feel more than capable rather than serve as a reminder of their vulnerability.

Design Directions

From research into the ways that able-bodied human beings prevent themselves from falling, or mitigate the intensity of a full fall, as well as research into how other animals adapted to falling emerged two directions that could be taken to develop a design solution.

Slowing

Designing for slowing is designing to manipulate the surrounding situation to accommodate for the user's natural level of ability

Stabilizing

Designing for stabilizing is designing to augment the user's ability to respond accordingly to naturally occurring situations

Idea 1: balancing belt

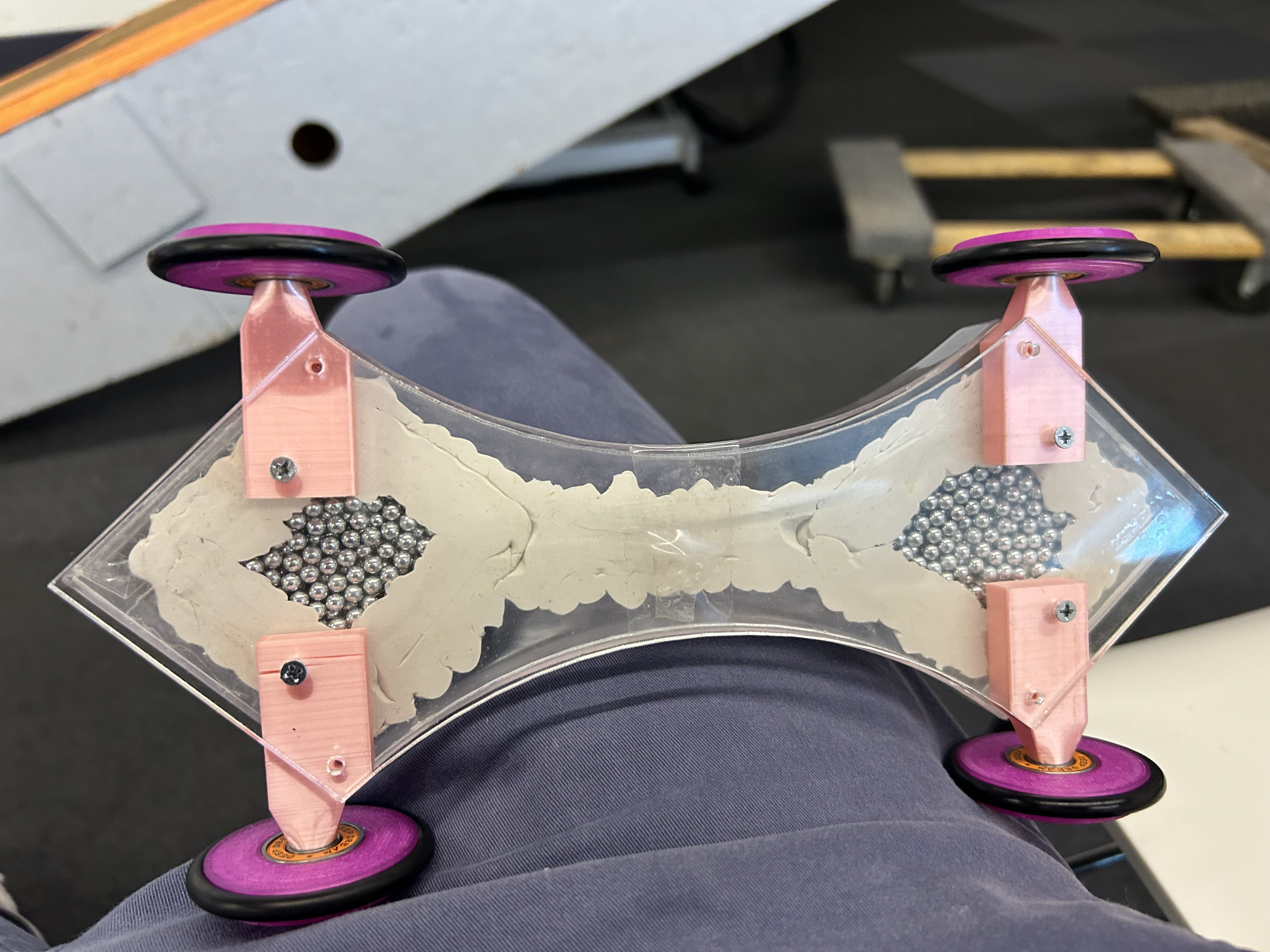

Putting together a quick prototype of the car concept for testing, I did not yet have the underbody component finished, and instead used the templated body structure of two acrylic plates, but with my custom-shaped plates instead. To test the car with weight, BBs were secured inside on top of the acrylic in a pocket formed by plasticine.

Idea 2: Artificial Leg

Putting together a quick prototype of the car concept for testing, I did not yet have the underbody component finished, and instead used the templated body structure of two acrylic plates, but with my custom-shaped plates instead. To test the car with weight, BBs were secured inside on top of the acrylic in a pocket formed by plasticine.

discovery

Putting together a quick prototype of the car concept for testing, I did not yet have the underbody component finished, and instead used the templated body structure of two acrylic plates, but with my custom-shaped plates instead. To test the car with weight, BBs were secured inside on top of the acrylic in a pocket formed by plasticine.

Idea 3: flywheel belt

Putting together a quick prototype of the car concept for testing, I did not yet have the underbody component finished, and instead used the templated body structure of two acrylic plates, but with my custom-shaped plates instead. To test the car with weight, BBs were secured inside on top of the acrylic in a pocket formed by plasticine.

Development

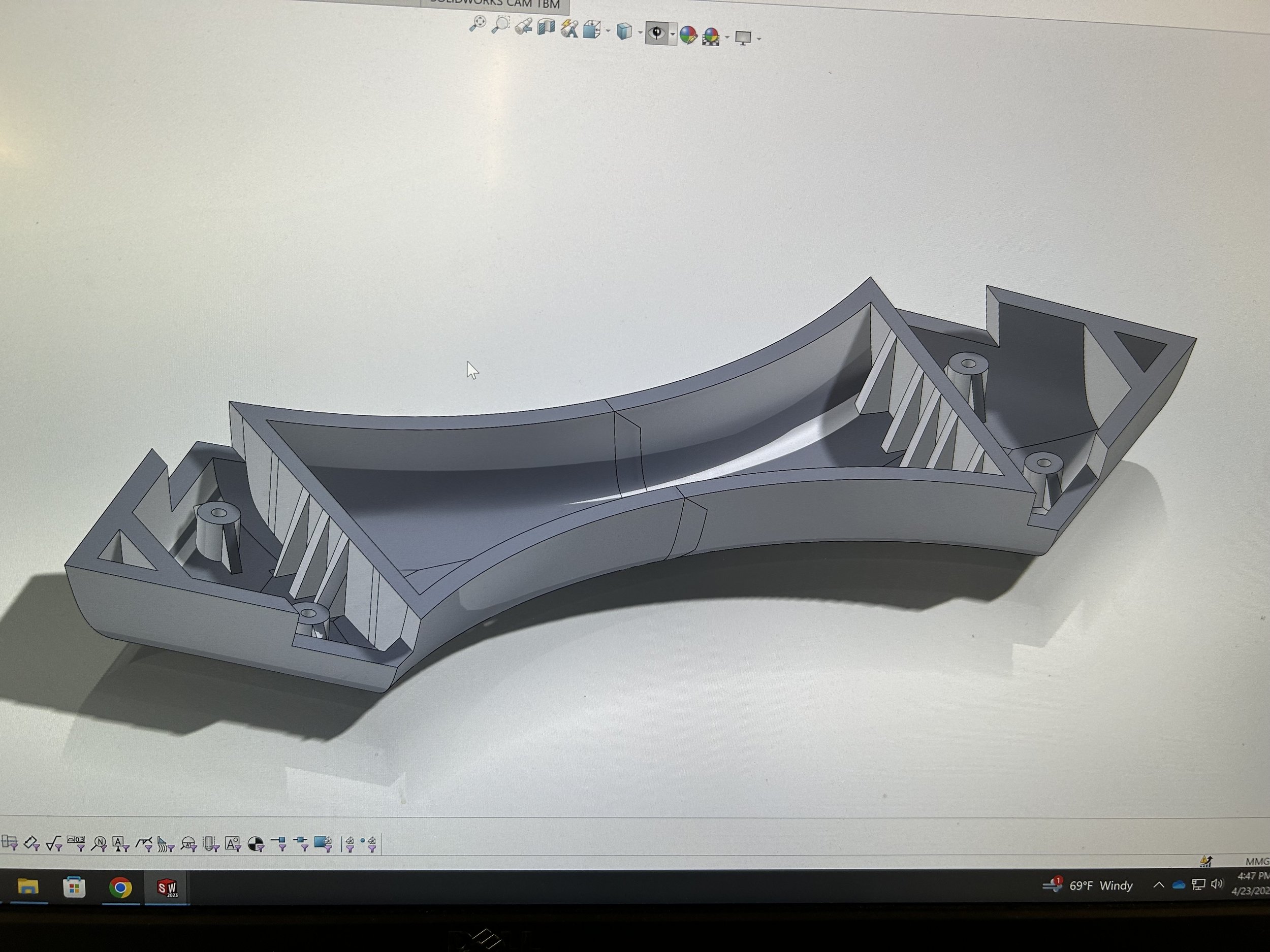

Underbody was made in two parts with a joining component for easier gluing. This was a result of not having a 3D printer with a big enough bed to print it in one piece.

Weight system had been originally designed for BBs. During testing, it was discovered that the BBs were interfering with mounting the acrylic plate onto the underbody. This resulted in BBs having to be removed, giving the BBs room to move around while the car was in motion. This motion pulled back on the car when it attempted to go up the counter-ramp. As a last minute fix, the BBs were replaced with metal bars, which were cut to fit into the underbody, mostly fixing the issue of movement.

The flywheel

Underbody was made in two parts with a joining component for easier gluing. This was a result of not having a 3D printer with a big enough bed to print it in one piece.

Weight system had been originally designed for BBs. During testing, it was discovered that the BBs were interfering with mounting the acrylic plate onto the underbody. This resulted in BBs having to be removed, giving the BBs room to move around while the car was in motion. This motion pulled back on the car when it attempted to go up the counter-ramp. As a last minute fix, the BBs were replaced with metal bars, which were cut to fit into the underbody, mostly fixing the issue of movement.

Maximalism

Underbody was made in two parts with a joining component for easier gluing. This was a result of not having a 3D printer with a big enough bed to print it in one piece.

Weight system had been originally designed for BBs. During testing, it was discovered that the BBs were interfering with mounting the acrylic plate onto the underbody. This resulted in BBs having to be removed, giving the BBs room to move around while the car was in motion. This motion pulled back on the car when it attempted to go up the counter-ramp. As a last minute fix, the BBs were replaced with metal bars, which were cut to fit into the underbody, mostly fixing the issue of movement.

Proving the concept

Underbody was made in two parts with a joining component for easier gluing. This was a result of not having a 3D printer with a big enough bed to print it in one piece.

Weight system had been originally designed for BBs. During testing, it was discovered that the BBs were interfering with mounting the acrylic plate onto the underbody. This resulted in BBs having to be removed, giving the BBs room to move around while the car was in motion. This motion pulled back on the car when it attempted to go up the counter-ramp. As a last minute fix, the BBs were replaced with metal bars, which were cut to fit into the underbody, mostly fixing the issue of movement.

Final Design

The final design for the automatic balancing device is grounded in reality rather than idealistic conceptualism. Backed by research and mathematical proof, this device could be made and used today.

Carrying weight

Easy equip buckle

Adjustability

Assembly

Outcome

The car was awarded Best Construction

The car did not end up being as fast as anticipated. This can be attributed to a rushed job degreasing and re-lubricating ball bearings prior to the race, which would have significantly improved speed.

No parts of the car broke, were damaged, or failed during the race.

Looking forward

The car was awarded Best Construction

The car did not end up being as fast as anticipated. This can be attributed to a rushed job degreasing and re-lubricating ball bearings prior to the race, which would have significantly improved speed.

No parts of the car broke, were damaged, or failed during the race.

What I Would Do Differently

Primarily: I would produce a full prototype faster for performance testing, allowing me to troubleshoot performance issues further in advance of the race.

As a result, I would have reworked the weight system

Either designing to better accommodate the BBs, or instead pivoting to using the metal rods

Focusing the weight system design on weighting primarily the rear of the vehicle, possibly scrapping symmetrical design.